Why do industries need an LMS?

Industries need LMS solutions to train large, shift-based workforces, prevent downtime, and ensure every worker meets equipment, safety, and compliance requirements.

Advantages of e-KHOOL LMS for industries

e-KHOOL LMS transforms industrial operations by building safer plants, improving process efficiency, and preparing workers for modern manufacturing challenges.

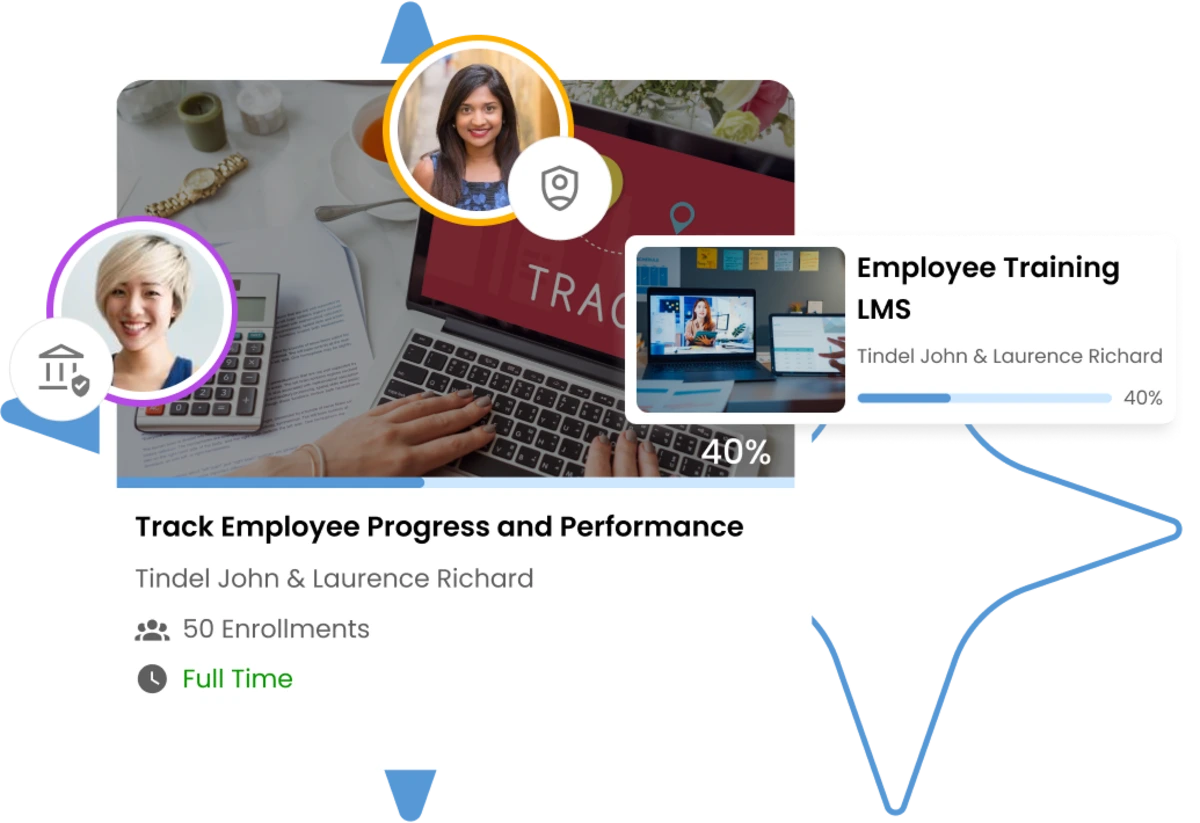

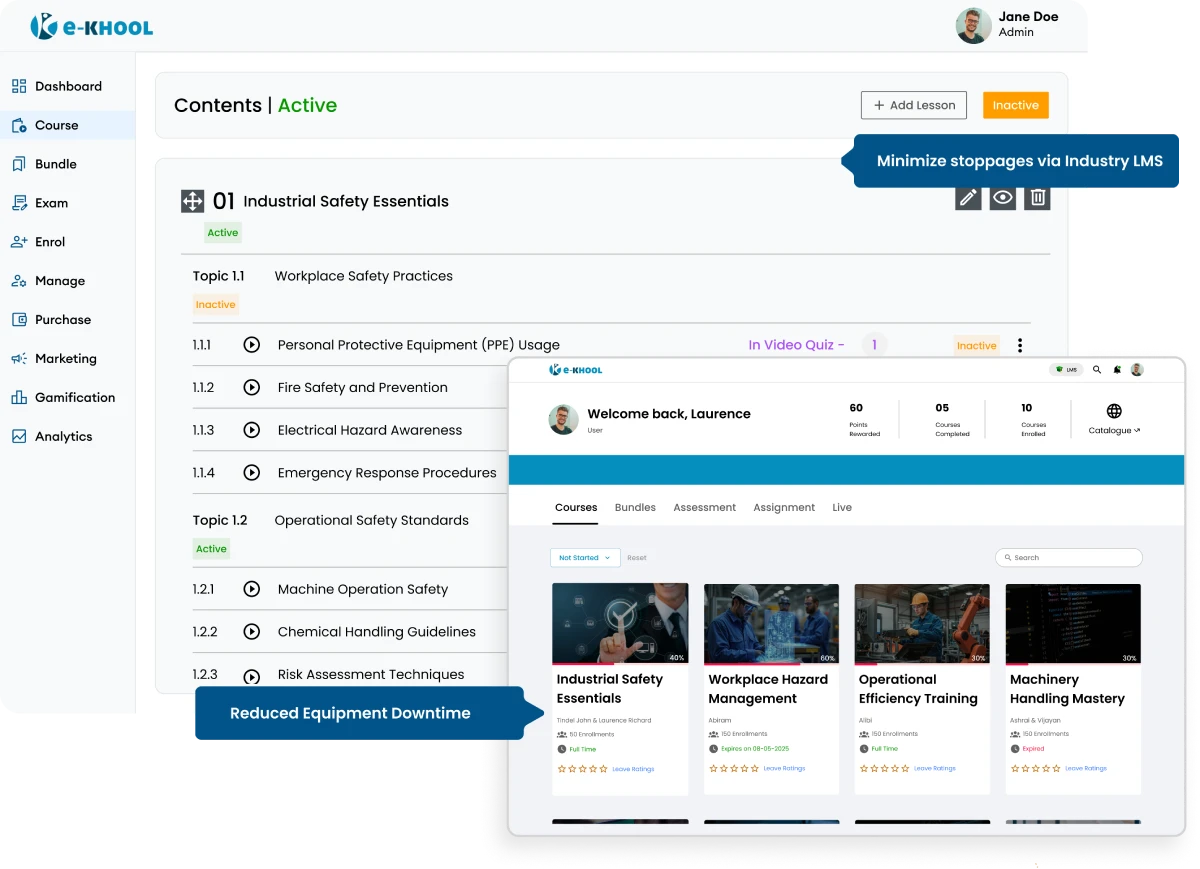

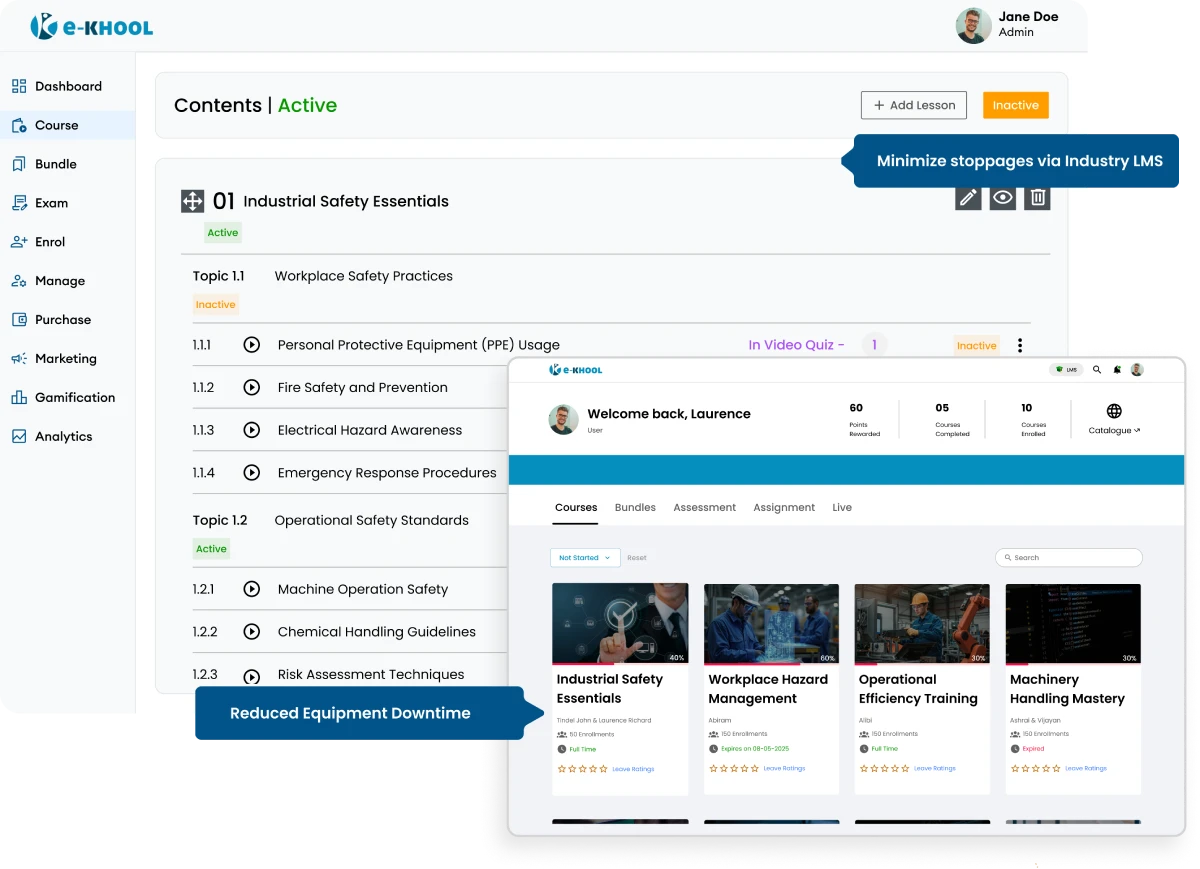

Reduced equipment downtime

Training modules teach operators preventive maintenance practices, ensuring fewer breakdowns and smoother production.

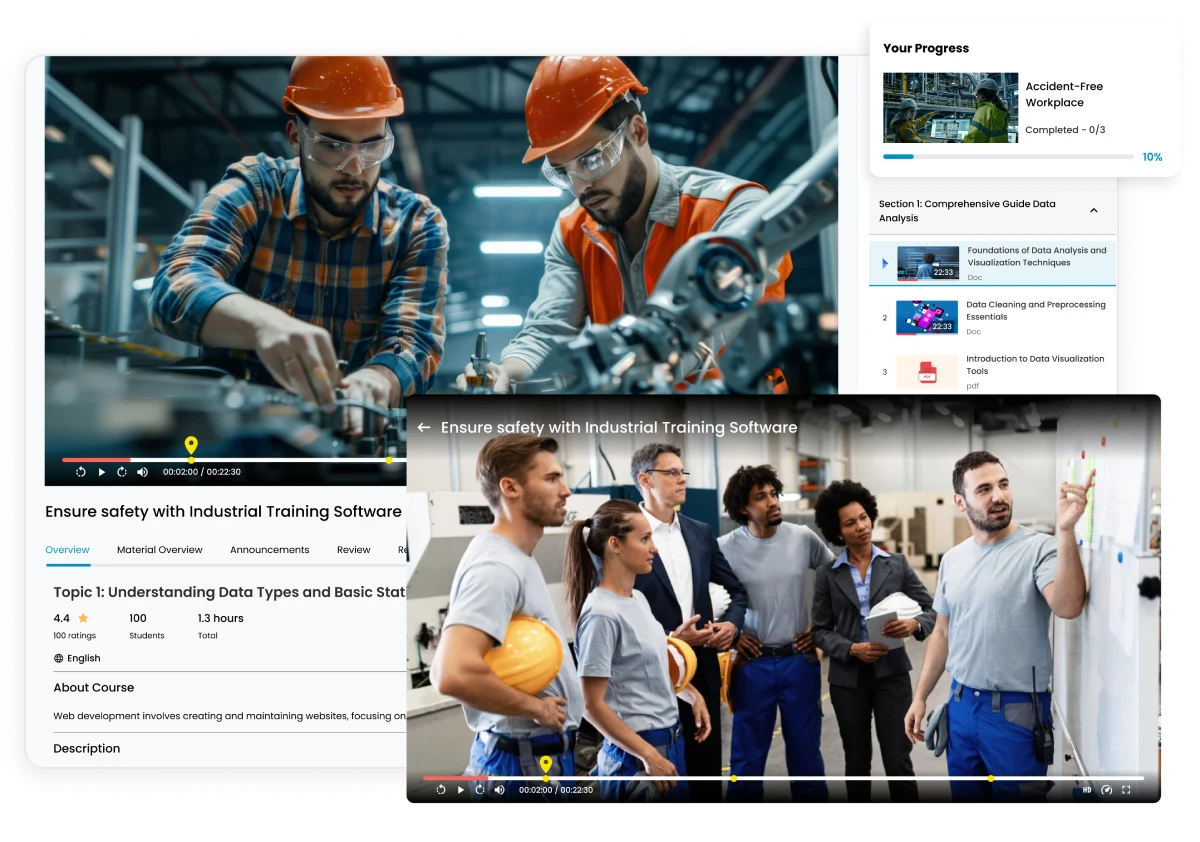

Accident-Free workplace

Simulation-based safety modules prepare workers for emergencies, lowering risks of accidents across high-risk industrial zones.

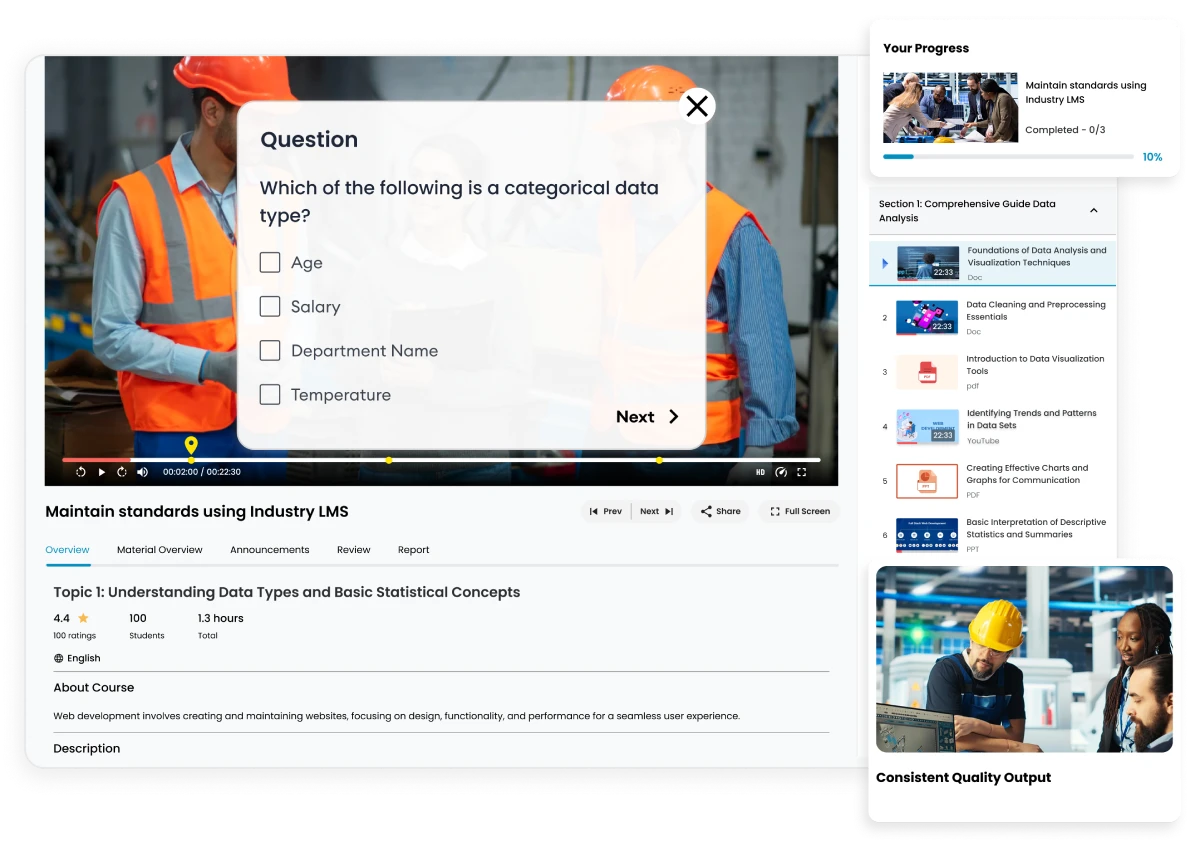

Consistent quality output

Course-driven QA training ensures every worker follows the same protocols, minimizing defects and maintaining consistent product quality.

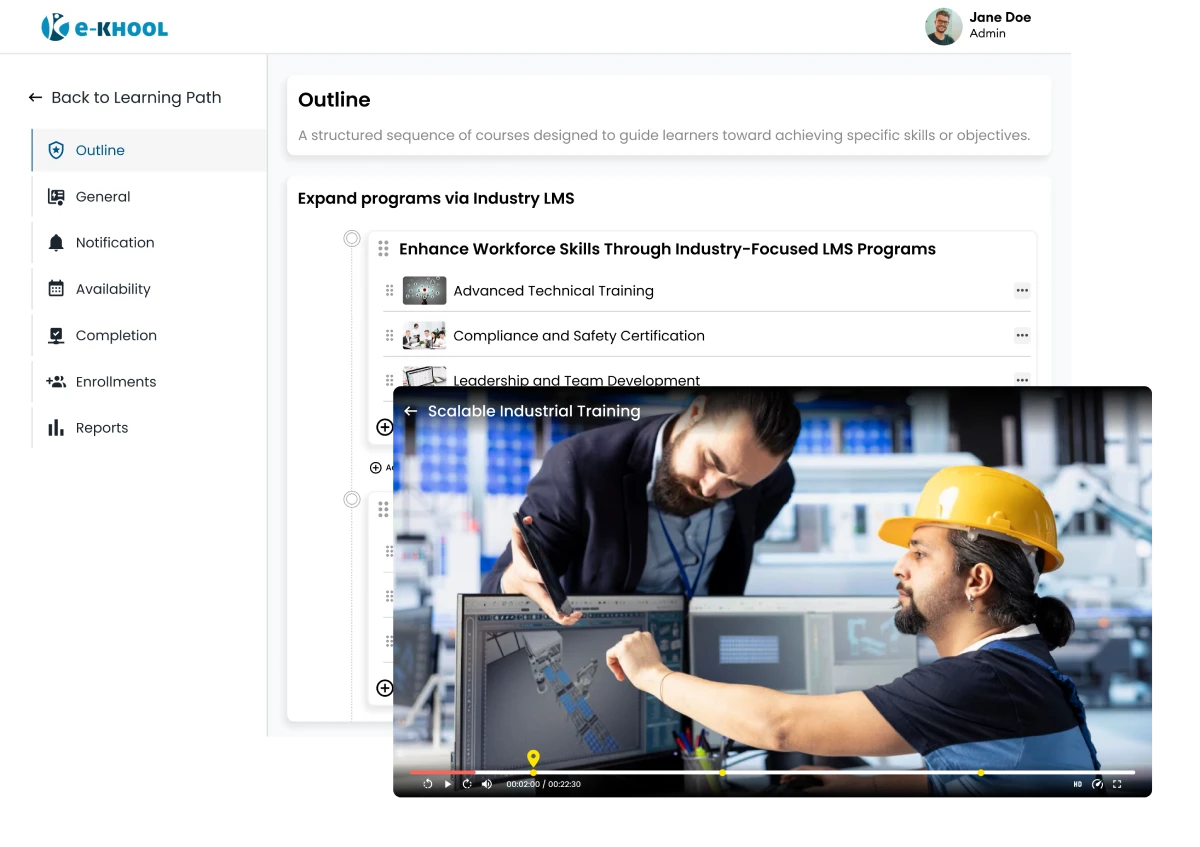

Scalable industrial training

Deploy industry-specific training across multiple plants and locations with multilingual and branch-based LMS features.

Transform workforce training with e-KHOOL LMS

Industrial success depends on skilled, safe, and compliant workers. e-KHOOL LMS ensures workforce readiness with real-world industrial training programs.

Digitize hazard response training

Create modules for fire safety, chemical handling, or electrical hazard management to prepare workers for emergencies.

Role-Based technical training

Deliver specialized learning paths for welders, machine operators, supervisors, and QA inspectors with hands-on learning simulations.

Multi-Plant certification management

Track workforce certifications across plants, automate renewals, and stay audit-ready with industrial compliance reports.